DIY Lab Magic: Brewing Your Own High-Fidelity PCR Enzyme

A cost-effective method for in-house Pfu DNA polymerase purification

Article Navigation

Forget expensive kits! Deep within research labs, a quiet revolution brews: scientists crafting their own ultra-accurate DNA copiers. This article dives into the world of in-house Pfu DNA polymerase purification – a clever, cost-effective method empowering labs to perform high-fidelity PCR without breaking the bank. Discover how a dash of biochemistry ingenuity lets researchers harness the power of an ancient microbe for cutting-edge genetics.

Why Precision DNA Copying Matters

Polymerase Chain Reaction (PCR) is the backbone of modern biology. It's how we amplify tiny snippets of DNA into workable amounts for sequencing, diagnostics, cloning, and forensics. But not all PCR is equal. Standard enzymes, like Taq polymerase, make copying errors – tiny typos in the genetic code. While acceptable for some tasks, these errors are disastrous for applications demanding pinpoint accuracy: studying cancer mutations, building synthetic genes, or analyzing ancient DNA.

Pfu DNA Polymerase

Hailing from the volcanic depths inhabited by Pyrococcus furiosus (literally "furious fireball"), this enzyme possesses a superpower: proofreading. It checks its work as it copies DNA, snipping out mismatched nucleotides. This results in significantly fewer errors – high-fidelity PCR.

The Problem: Pricey Perfection

Commercial high-fidelity PCR kits, featuring purified Pfu or similar enzymes, are reliable but notoriously expensive. For labs running hundreds or thousands of reactions, this cost becomes prohibitive. This is where the art of in-house purification shines. By expressing the Pfu gene in E. coli bacteria and purifying the enzyme themselves, labs can slash costs dramatically while maintaining exceptional quality.

Heat Stability

Pfu thrives near boiling water. Most E. coli proteins melt (denature) at these temperatures, but Pfu remains perfectly folded and active.

Affinity Tags

Scientists modify the Pfu gene to include a small "tag," like 6xHis (six histidine amino acids in a row). This tag acts like a molecular handle.

The Key Experiment: Purifying Pfu – Step by Step

Let's walk through a core method used by many labs, often called Heat Treatment followed by Immobilized Metal Affinity Chromatography (IMAC).

Hypothesis

Recombinant His-tagged Pfu polymerase expressed in E. coli can be efficiently purified using its heat stability and affinity for nickel ions, yielding an enzyme with fidelity and activity comparable to commercial versions at a fraction of the cost.

Methodology:

-

Gene Expression

The gene for Pfu polymerase (engineered to include a 6xHis tag) is inserted into E. coli bacteria. The bacteria are grown in large flasks until dense.

-

Induction

A chemical (like IPTG) is added, "turning on" the bacteria's machinery to mass-produce the His-tagged Pfu protein.

-

Harvest & Lysis

Bacteria are collected by centrifugation. The cells are broken open (lysed) using enzymes or physical force to release their contents, including Pfu, into a slurry (lysate).

-

Heat Shock (The Magic Step)

The lysate is heated to ~75-80°C for 15-30 minutes.

What Happens: Most E. coli proteins denature – they unfold and become insoluble, forming a thick precipitate. His-tagged Pfu, loving the heat, remains perfectly soluble and active. -

Clarification

The heated mixture is spun in a centrifuge. The denatured E. coli gunk forms a pellet. The clear supernatant (liquid on top) contains the precious, soluble His-tagged Pfu and a few other very heat-resistant proteins.

-

Affinity Capture (IMAC)

The supernatant is passed through a chromatography column packed with beads coated with Nickel ions (Ni²⁺).

What Happens: The 6xHis tag on the Pfu protein has a high affinity for nickel. Pfu sticks tightly to the beads. Other proteins in the supernatant flow through the column. -

Washing

The column is washed with a buffer containing a low concentration of imidazole (a molecule that mimics histidine). This removes any proteins weakly sticking to the beads.

-

Elution

A buffer containing a high concentration of imidazole is passed through the column. Imidazole competes with the His-tag, knocking the Pfu polymerase off the nickel beads. This collected liquid is pure Pfu!

-

Dialysis/Buffer Exchange

The purified Pfu in imidazole buffer is transferred into its ideal storage buffer (often containing glycerol) using dialysis or specialized filters. This removes the imidazole and stabilizes the enzyme.

-

Quality Control

Activity is tested using a standard PCR reaction. Fidelity is assessed using specialized mutation detection assays.

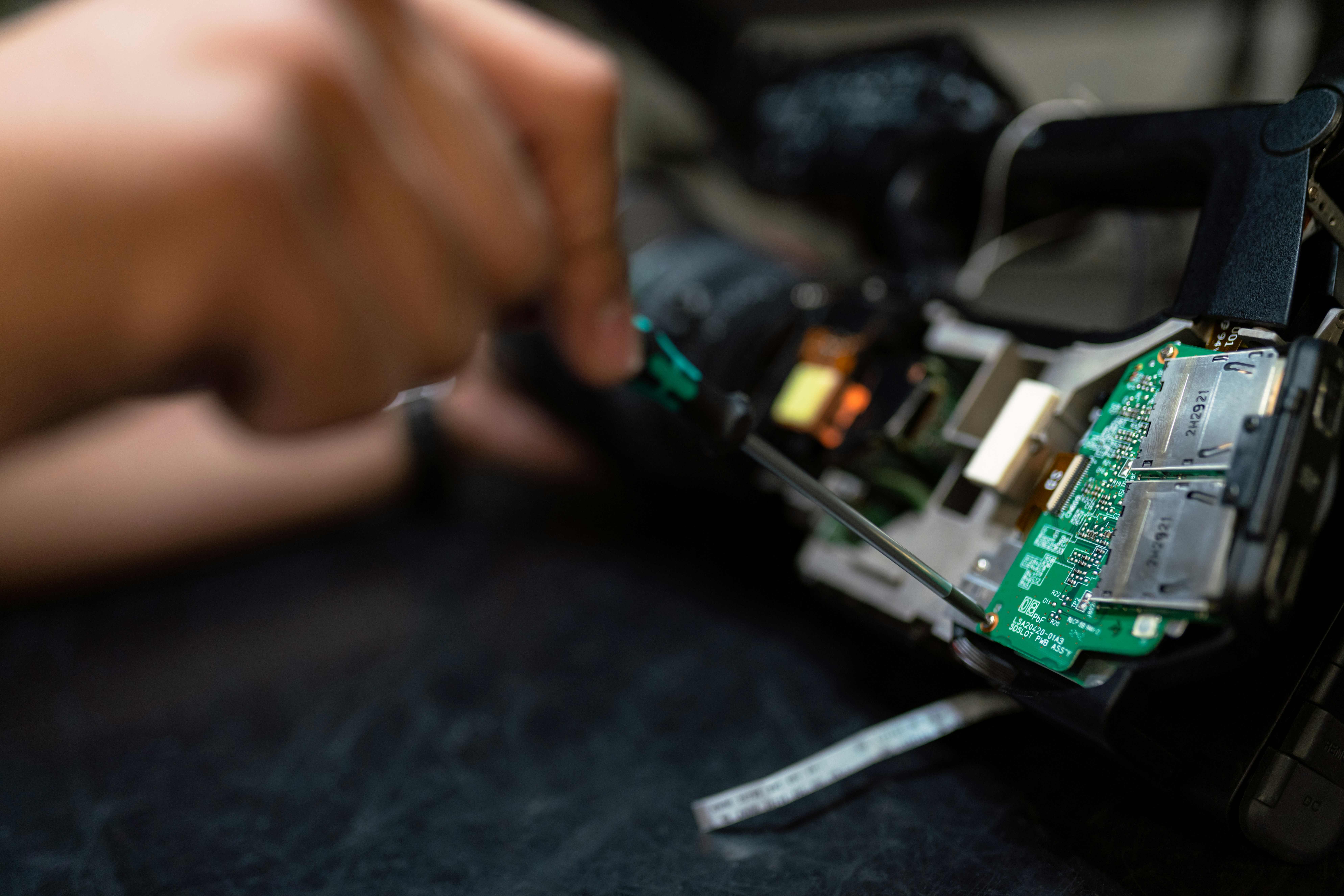

The purification process leverages Pfu's heat stability and affinity tags

Results and Analysis: Proof in the Performance

This straightforward method delivers impressive results:

High Purity

The heat step eliminates >90% of contaminating E. coli proteins. IMAC captures nearly all His-tagged Pfu, resulting in a preparation that's typically >95% pure Pfu polymerase (visible as a single dominant band on a protein gel).

Robust Activity

The purified enzyme performs robust PCR amplification across a range of template types and sizes, comparable to commercial Pfu enzymes.

Exceptional Fidelity

Crucially, fidelity tests confirm the purified enzyme retains its powerful proofreading activity, generating PCR products with error rates up to 10x lower than Taq polymerase.

Massive Cost Savings

The primary driver! Producing Pfu in-house reduces the cost per reaction by 50-90% compared to buying commercial high-fidelity kits.

Data Tables: The Numbers Speak

| Purification Source | Estimated Cost per 1000 units* | Primary Advantage | Primary Disadvantage |

|---|---|---|---|

| In-House (DIY) | $10 - $50 | Very Low Cost | Requires lab time & expertise |

| Commercial Kit | $200 - $800+ | Convenience, Guaranteed QC, Speed | High Reagent Cost |

| *Note: Unit definitions vary. Costs are illustrative estimates based on common lab scales and exclude equipment overhead. DIY costs cover bacteria growth media, induction chemicals, chromatography resins, and buffers. | |||

| Property | Typical Result (DIY Purification) | Importance |

|---|---|---|

| Purity | >95% (SDS-PAGE) | Reduces non-specific reactions, increases yield |

| Specific Activity | 10,000 - 30,000 units/mg protein | Measures catalytic power; comparable to commercial |

| Processivity | Medium | How many nucleotides added per binding event |

| Fidelity (Error Rate) | 1-2 x 10⁻⁶ errors/base | 5-10x better than Taq; critical for accuracy |

| Thermostability | Excellent (>2h half-life @ 95°C) | Essential for repeated high-temperature cycling |

Table 3: Impact of Heat Treatment Step

| Sample | Total Protein (mg) | Pfu Activity (Units) | % Activity Recovery | Major Contaminants? |

|---|---|---|---|---|

| Crude Lysate | 1000 | 100,000 | 100% | High (Thousands) |

| Post-Heat Supernatant | 100 | 95,000 | ~95% | Low (Most denatured) |

| Illustrates the dramatic purification achieved simply by heating. Over 90% of contaminating protein is removed or denatured, while nearly all active Pfu remains in solution. | ||||

The Scientist's Toolkit: Essentials for DIY Pfu Purification

Here's what a lab needs to brew their own high-fidelity enzyme:

Reagents and Solutions

Expression Plasmid

Contains the engineered Pfu gene with the His-tag. The instruction manual for the bacteria.

E. coli Strain

Workhorse bacteria genetically modified to express the plasmid's gene.

LB Growth Media

Nutrient broth to grow large quantities of E. coli.

IPTG

The "on switch" that induces the bacteria to produce Pfu polymerase.

Lysis Buffer

Breaks open the E. coli cells to release Pfu and other proteins.

Nickel-NTA Resin

Chromatography beads that bind the His-tag on Pfu via nickel ions. Core of IMAC.

Wash Buffer

Low imidazole buffer; removes weakly bound contaminants from the resin.

Elution Buffer

High imidazole buffer; competes with His-tag to release pure Pfu from the resin.

Dialysis Buffer / Storage Buffer

Stabilizes purified Pfu, removes imidazole, often contains glycerol for freezing.

PCR Reagents

(dNTPs, Primers, Template DNA, Mg²⁺) To test the activity and fidelity of the final purified enzyme.

Empowering Discovery, One Reaction at a Time

In-house Pfu purification is more than just a cost-cutting measure; it's an empowering technique. It democratizes access to high-fidelity PCR, allowing smaller labs, teaching institutions, and resource-limited settings to perform sophisticated genetic analyses previously hindered by reagent costs. The method embodies the resourcefulness at the heart of science – leveraging fundamental biochemical properties (heat stability, affinity tags) to solve practical problems.

While it requires some initial setup and expertise, the payoff in savings and self-sufficiency is immense. So, the next time you hear about a breakthrough in genetic research, remember: it might just have been powered by a home-brewed enzyme, purified with a little heat and some biochemical ingenuity, straight from the depths of a lab freezer. After all, sometimes the best tools aren't just bought off the shelf – they're crafted by the scientists who need them.